-

Sales & Customer Support

+1 (303) 706-1183

-

Hours of Operation

Mon - Fri 09.00 - 17.00 (MST)

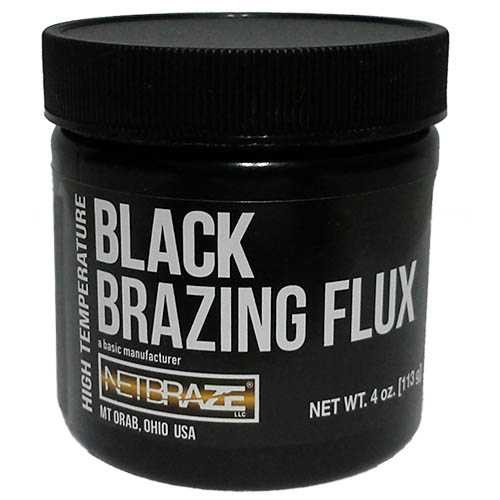

Netbraze Black Hi-Temp Brazing Flux

NetBraze BLACK BRAZING FLUX is recommended for the prolonged heating cycle of heavy parts or stainless applications. BLACK FLUX meets classification **AWS FB3-C for general purpose brazing and contains elemental Boron. Not recommended for aluminum, magnesium or titanium.

Base price for variant:

Sales price:

Sales price without tax:

Discount:

Tax amount:

Price / kg:

Description:

NetBraze BLACK BRAZING FLUX is recommended for the prolonged heating cycle of heavy parts or stainless applications. BLACK FLUX meets classification **AWS FB3-C for general purpose brazing and contains elemental Boron. Not recommended for aluminum, magnesium or titanium. CLEANING FLUX AFTER BRAZING: After brazing, flux should be removed from the braze parts, as it might cause corrosion to the assembly. Fluxes can be easily removed by flushing with hot water right after brazing, but the parts should be checked for thermal shock to the braze area. Often, when the parts have not been well cleaned the flux remainder, takes on a glass like structure an is difficult to remove. Difficult flux residues, due to prolonged brazing, can be removed by brushing, hot team cleaning or by chemical processes. SAFETY ISSUES: Safety is a serious concern in the brazing process. Hazardous ingredients may be present in the fluxes and in the gasses the fluxes produce. EXCELLENT VENTILATION IS A NECESSITY. Â Read and understand the MSDS (Material Safety Data Sheets).Reviews

There are yet no reviews for this product.